How to Make a Claw Paper

Claw paper is a type of handmade paper that is made from the fibers of claws. It is a strong and durable paper that is often used for making origami and other paper crafts. Claw paper is also a popular choice for making greeting cards and other types of paper goods.

To make claw paper, you will need the following materials:

- Claws

- Water

- A blender or food processor

- A mold and deckle

- A press

The first step is to clean the claws. You can do this by soaking them in water for a few hours. Once the claws are clean, you can remove the meat and other soft tissue.

Next, you will need to grind the claws into a pulp. You can do this using a blender or food processor. Add water to the blender or food processor until the pulp is a smooth consistency.

Once the pulp is ready, you can add it to the mold and deckle. The mold and deckle are two pieces of wood that are used to form the paper. The mold has a screen on the bottom that allows the water to drain away. The deckle is placed on top of the mold and helps to keep the pulp in place.

Once the pulp is in the mold and deckle, you can press it to remove the excess water. You can do this using a press or by placing a heavy object on top of the mold and deckle.

Once the paper is dry, you can remove it from the mold and deckle. The paper will be strong and durable, and it can be used for a variety of purposes.

How to Make a Claw Paper

Making claw paper involves several essential aspects. Understanding these aspects is crucial for successful papermaking.

- Claws: The choice of claws significantly impacts the paper’s strength and texture.

- Grinding: The process of breaking down claws into pulp determines the paper’s smoothness.

- Mold: The shape and size of the mold influence the paper’s dimensions and form.

- Pressing: Applying pressure removes excess water, affecting the paper’s thickness and durability.

- Drying: Proper drying techniques ensure the paper’s stability and prevent warping.

Each aspect plays a vital role in crafting unique and beautiful claw paper. The selection of claws, grinding technique, mold design, pressing method, and drying conditions all contribute to the final characteristics of the paper. Understanding these aspects empowers papermakers to tailor their creations for specific purposes and artistic expressions.

1. Claws

In the art of claw papermaking, the selection of claws holds paramount importance. Different species and ages of claws yield distinct fibers, directly influencing the paper’s physical characteristics. For instance, the claws of larger animals, such as bears or wolves, produce sturdier fibers, resulting in a more robust and durable paper. Conversely, the claws of smaller animals, like rabbits or squirrels, yield finer fibers, imparting a delicate and pliable texture to the paper.

The age of the claws also plays a significant role. Juvenile claws possess a higher collagen content, contributing to increased flexibility and softness in the paper. As claws mature, the collagen content decreases, resulting in a denser and more rigid paper. Understanding the properties of claws from different sources empowers papermakers to tailor their creations for specific applications.

For instance, paper crafted from the claws of bears might be ideal for creating sturdy book covers or durable maps, while paper made from the claws of rabbits could lend itself to delicate origami or intricate artwork. Recognizing the connection between claw selection and paper characteristics empowers papermakers to make informed choices, ensuring their creations possess the desired qualities.

2. Grinding

In the art of claw papermaking, the process of grinding claws into pulp plays a pivotal role in determining the smoothness of the final product. The coarseness or fineness of the pulp directly influences the texture and appearance of the paper.

Coarser pulp, achieved through minimal grinding, yields paper with a rough and textured surface, resembling the natural texture of the claws. This type of paper finds applications in creating rustic and tactile pieces, such as decorative covers or packaging materials. Conversely, finely ground pulp produces a smooth and uniform surface, ideal for writing, drawing, or creating delicate origami. The lends itself to applications where precision and aesthetics are paramount.

The choice of grinding technique and the duration of the process depend on the desired outcome. For instance, extended grinding using a blender or a mortar and pestle produces a finer pulp, while shorter grinding times or the use of coarser grinding tools result in a more textured pulp. Understanding the connection between grinding and paper smoothness empowers papermakers to tailor their techniques to achieve the specific characteristics they seek in their creations.

3. Mold

In the art of claw papermaking, the mold serves as a defining element, shaping the dimensions and form of the final product. Its intricate relationship with the papermaking process warrants exploration to fully grasp its significance.

-

Shape

The mold’s shape determines the paper’s outline and overall form. Common shapes include rectangular, square, and circular molds, each yielding distinct aesthetic qualities. Rectangular molds produce papers suitable for writing, bookbinding, or creating origami pieces. Square molds offer versatility, allowing for both functional and decorative purposes. Circular molds, with their unique curvature, lend themselves to creating lampshades, bowls, or decorative elements. -

Size

The mold’s size directly influences the dimensions of the paper. Larger molds produce sheets suitable for larger projects, such as maps, posters, or art prints. Smaller molds yield more delicate sheets, ideal for intricate artwork, jewelry making, or creating miniature books. -

Material

The material of the mold affects the texture and finish of the paper. Traditional molds are often made of wood, imparting a natural grain pattern onto the paper’s surface. Metal molds, on the other hand, produce a smoother finish with sharper edges. The choice of mold material depends on the desired aesthetic and functional qualities of the paper. -

Design

The mold’s design encompasses not only its shape and size but also any additional features or embellishments. Some molds incorporate raised designs or textures, transferring these patterns onto the paper’s surface. This technique allows for the creation of highly decorative papers suitable for specialized applications such as invitations, gift wrapping, or book covers.

Understanding the connection between mold and paper form empowers papermakers to envision and create papers tailored to specific purposes and artistic expressions. By carefully selecting the mold’s shape, size, material, and design, papermakers can craft unique and captivating pieces that transcend the boundaries of ordinary paper.

4. Pressing

In the art of claw papermaking, the pressing stage plays a critical role in shaping the final characteristics of the paper. As pressure is applied, excess water is removed from the freshly formed sheet, directly influencing its thickness and durability.

The thickness of the paper is inversely proportional to the pressure applied. Higher pressure results in thinner paper, while lower pressure yields thicker paper. This relationship allows papermakers to control the thickness of their creations, tailoring it to specific applications. For instance, thin paper is ideal for origami or lampshades, while thicker paper is better suited for book covers or packaging.

Durability is another crucial aspect affected by pressing. The application of pressure helps to bond the fibers of the paper more tightly, increasing its strength and resistance to tearing. Well-pressed paper is less likely to wrinkle or tear, making it more durable and suitable for long-lasting use.

The pressing stage also influences the paper’s surface texture. Higher pressure creates a smoother surface, while lower pressure results in a more textured surface. This variation in texture can be used to achieve different aesthetic effects or to enhance the paper’s functionality.

Understanding the connection between pressing and paper properties empowers papermakers to manipulate this stage to achieve desired outcomes. By carefully controlling the amount of pressure applied, papermakers can create papers with specific thicknesses, durabilities, and surface textures, meeting the demands of diverse applications and artistic visions.

5. Drying

Drying is an essential step in the papermaking process that significantly impacts the final quality and properties of the paper. Improper drying can lead to warping, shrinking, or cracking, compromising the paper’s stability and durability. Understanding the principles of proper drying techniques is crucial for achieving successful results in claw papermaking.

-

Temperature Control

Temperature plays a critical role in drying paper. Excessive heat can cause the paper to warp or buckle, while insufficient heat can lead to mold growth. Maintaining a consistent and moderate temperature throughout the drying process is essential to ensure the paper dries evenly and without damage.

-

Humidity Control

Humidity levels also affect the drying process. High humidity can slow down drying, while low humidity can cause the paper to become brittle. Controlling the humidity levels in the drying environment helps to ensure that the paper dries at an optimal rate, preventing warping or cracking.

-

Air Circulation

Adequate air circulation is essential for efficient and uniform drying. Stagnant air can trap moisture in certain areas of the paper, leading to uneven drying and potential warping. Ensuring good air circulation throughout the drying space promotes consistent drying and helps prevent these issues.

-

Drying Time

The drying time depends on several factors, including the thickness of the paper, the temperature, and humidity levels. It is important to allow sufficient time for the paper to dry thoroughly. Rushing the drying process can result in incomplete drying, making the paper more susceptible to warping or damage.

By adhering to proper drying techniques and carefully controlling temperature, humidity, air circulation, and drying time, papermakers can ensure the stability and durability of their claw paper creations. Understanding the intricacies of the drying process empowers papermakers to produce high-quality papers that are resistant to warping and other forms of damage.

Creating Claw Paper

The art of claw papermaking encompasses a diverse range of techniques and applications. Here are six examples of claw paper creations, along with guidelines, tips, and benefits for each:

-

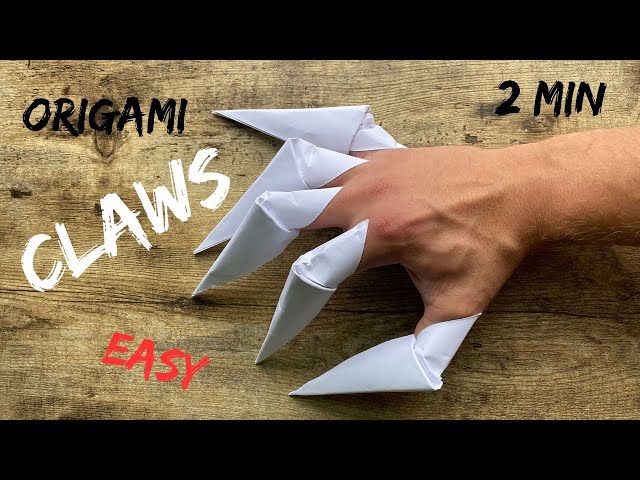

Example 1: Origami Paper

Guidelines: Use thin and pliable paper to achieve intricate folds and shapes. Experiment with different claw species to create papers with varying textures and strengths.

-

Example 2: Lamp Shades

Guidelines: Choose translucent or semi-translucent paper to allow light to pass through. Consider using larger claws to create a more durable paper suitable for lampshade construction.

-

Example 3: Jewelry

Guidelines: Use finely ground pulp to create smooth and delicate paper. Experiment with adding pigments or dyes to the pulp to create colorful and visually striking pieces.

-

Example 4: Book Covers

Guidelines: Opt for thicker and more durable paper to protect the contents of the book. Consider using a combination of claws and other fibers to enhance the paper’s strength and longevity.

-

Example 5: Wall Art

Guidelines: Explore different molding techniques to create unique textures and patterns. Use natural or dyed claws to achieve a wide range of colors and visual effects.

-

Example 6: Packaging

Guidelines: Consider the functional requirements of the packaging, such as strength, durability, and moisture resistance. Use appropriate claw species and pressing techniques to create paper that meets these demands.

Tips for Claw Papermaking:

Tip 1: Experiment with different claw species to achieve varying paper textures and strengths. Larger claws yield stronger fibers, while smaller claws produce more delicate fibers.

Tip 2: Control the grinding process to achieve the desired pulp smoothness. Finer grinding results in smoother paper, while coarser grinding creates a more textured finish.

Tip 3: Use appropriate molds to shape and size the paper. The shape and size of the mold will determine the final dimensions and form of the paper.

Tip 4: Apply the correct amount of pressure during pressing to control the paper’s thickness and durability. Higher pressure results in thinner and more durable paper.

Tip 5: Ensure proper drying techniques to prevent warping and ensure stability. Control temperature, humidity, air circulation, and drying time to achieve optimal results.

Benefits of Claw Paper:

Claw paper offers several advantages, including:

- Strength and Durability: Claw fibers create strong and durable paper, making it suitable for various applications.

- Unique Textures: The natural textures of claws impart a distinct and visually appealing character to the paper.

- Biodegradability: Claw paper is biodegradable, contributing to environmental sustainability.

- Versatility: Claw paper can be used in a wide range of applications, from origami to packaging to artwork.

Understanding the techniques, guidelines, tips, and benefits of claw papermaking empowers individuals to create unique and functional paper products. By experimenting with different methods and materials, papermakers can push the boundaries of this ancient craft and produce remarkable and sustainable works of art.

FAQs on Claw Papermaking

This section addresses frequently asked questions and misconceptions surrounding the art of claw papermaking, providing clear and informative answers.

Question 1: What are the advantages of using claws in papermaking?

Claws offer unique advantages in papermaking, including their inherent strength and durability. The fibers found in claws contribute to the creation of sturdy and long-lasting paper, making it suitable for various applications.

Question 2: How does the choice of claws impact the paper’s characteristics?

The selection of claws significantly influences the paper’s properties. Different species and ages of claws yield distinct fibers, affecting the paper’s strength, texture, and overall appearance. Larger claws typically produce stronger fibers, while smaller claws contribute to a more delicate and pliable paper.

Question 3: What is the optimal grinding technique for claw papermaking?

The grinding technique plays a crucial role in determining the smoothness of the paper. Finer grinding using a blender or mortar and pestle results in a smoother pulp, while coarser grinding techniques yield a more textured finish. The choice of grinding method depends on the desired outcome and the intended application of the paper.

Question 4: How does pressing affect the paper’s properties?

Pressing is an essential step that influences the paper’s thickness and durability. Applying pressure removes excess water from the freshly formed sheet, resulting in a thinner and more compact paper. Higher pressure generally leads to thinner and more durable paper, while lower pressure yields thicker and more flexible paper.

Question 5: What are the key considerations for drying claw paper?

Proper drying techniques are crucial to prevent warping and ensure the stability of the paper. Controlling temperature, humidity, air circulation, and drying time is essential. Maintaining a consistent and moderate temperature, managing humidity levels, ensuring adequate air circulation, and allowing sufficient drying time contribute to the creation of high-quality claw paper.

Question 6: What are some creative applications of claw paper?

Claw paper’s versatility extends beyond traditional uses. It finds applications in origami, creating delicate and intricate folded forms. As lampshades, it allows for unique light diffusion and adds a touch of natural elegance to any space. Jewelry made from claw paper showcases its durability and beauty, while book covers crafted from this material offer both protection and an artistic flair. Additionally, claw paper can be incorporated into packaging, adding an eco-conscious and visually appealing element.

These FAQs provide a comprehensive overview of common queries and misconceptions surrounding claw papermaking. Understanding these aspects empowers papermakers to make informed decisions, explore creative possibilities, and produce exceptional claw paper creations.

Transition to the next article section…

Conclusion

The exploration of “how to make a claw paper” unveils a multifaceted process that encompasses various aspects, from the selection of claws and grinding techniques to mold design, pressing methods, drying conditions, and creative applications. Understanding these elements empowers papermakers to craft unique and beautiful claw paper tailored to specific purposes and artistic expressions.

Claw papermaking transcends mere paper production; it is an art form that invites experimentation, innovation, and the celebration of nature’s materials. By embracing sustainable practices and harnessing the inherent qualities of claws, papermakers contribute to the preservation of traditional crafts while pushing the boundaries of creativity.

The versatility of claw paper extends beyond traditional uses, inspiring contemporary applications in diverse fields such as origami, jewelry making, lampshade design, bookbinding, and packaging. Its strength, durability, and unique textures offer endless possibilities for artistic exploration and functional implementation.

As we delve deeper into the world of claw papermaking, we uncover a rich tapestry of cultural heritage, environmental consciousness, and boundless creative potential. May this exploration inspire you to embrace the art of claw papermaking, to create beautiful and sustainable works of art that connect us to the natural world.

Youtube Video: